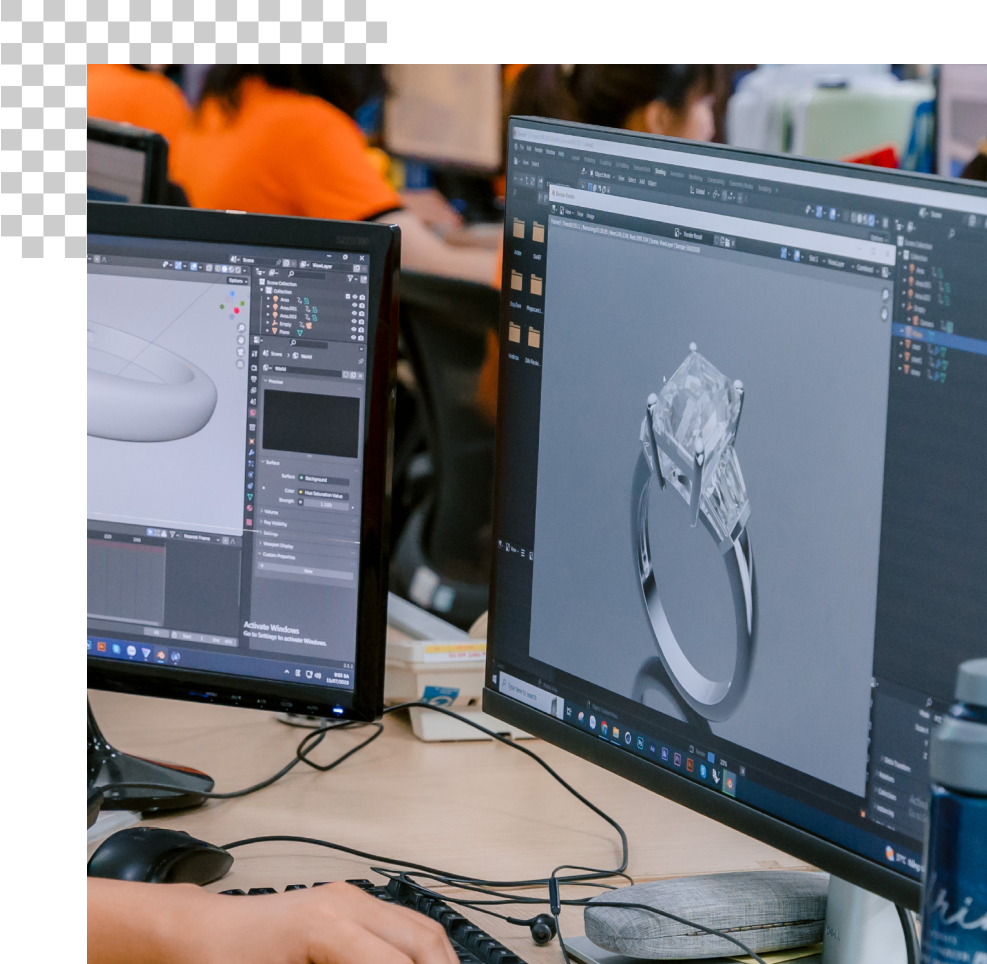

Design Process

We're dedicated to bringing your vision to life. Whether your concept begins as a rough sketch or a verbal description, our team of skilled designers will transform your ideas into precise CAD models. This process ensures that every nuance of your design is captured with accuracy, allowing us to craft your piece with detail and exceptional quality.

1

Design Concept & Requirements

2

R&D

3

2D Design

4

Confirm Designs

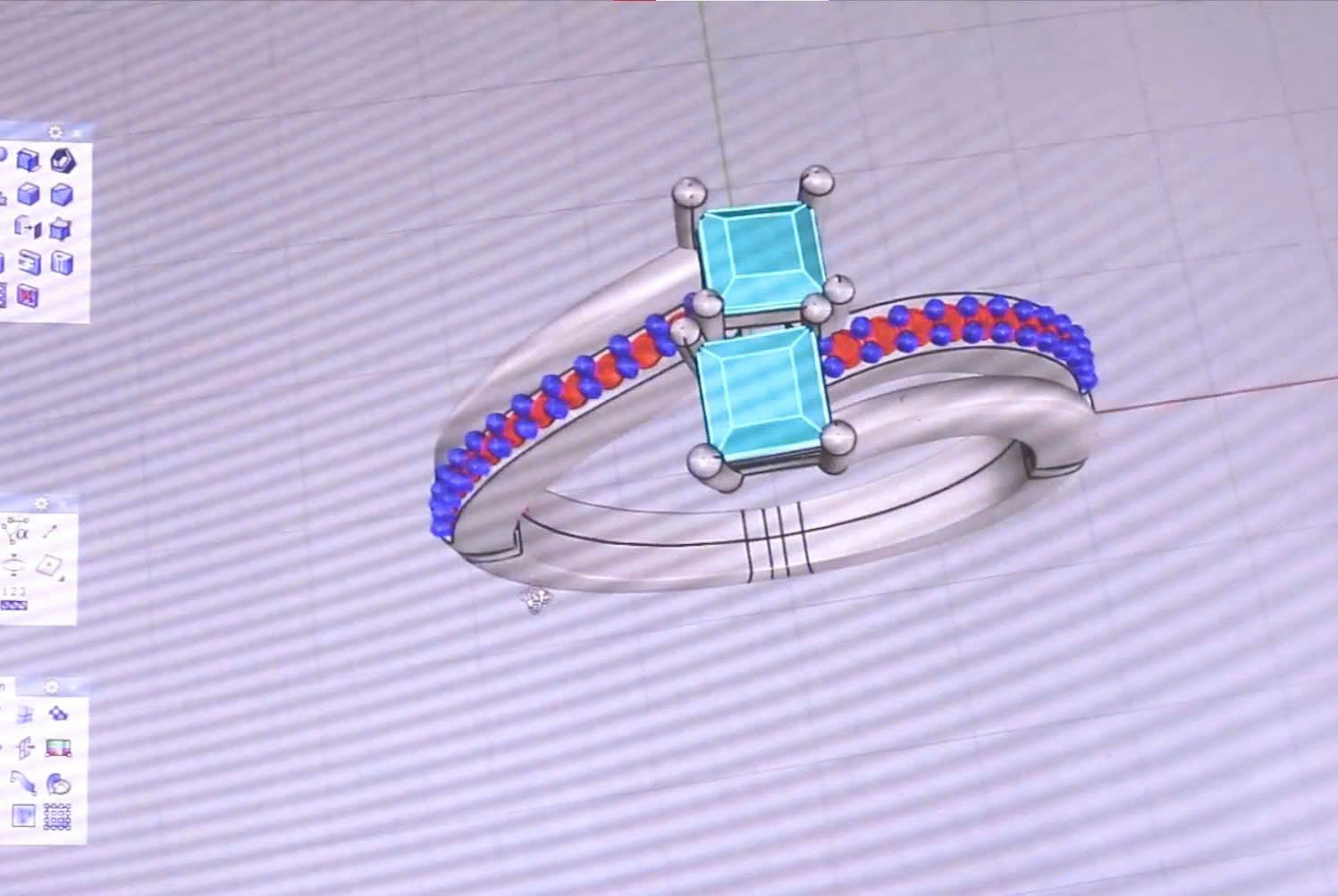

Sampling Process

Jewelry sampling is a crucial step in the production process, offering customers the chance to bring their design to life before committing to a larger order. Through sampling, customers can visualize their concept, assess the quality of materials, and evaluate the craftsmanship firsthand.

For designers, it's an invaluable opportunity to refine ideas, address potential issues, and perfect the final design. Manufacturers benefit by testing the feasibility of the design and identifying the most efficient production methods.

1

Request

2

CAD (3D design)

3

Printing Molds (Wax and Silicone)

4

Stone Setting & Casting

5

Finishing Sample

Jewelry Making Process

1. Design

The design process is the foundation of our jewelry creation, where we collaborate closely with our clients to develop unique, personalized pieces. Using advances software such as CAD, we precisely model each design to ensure accurate visualization before production. From initial sketches to 3D renderings, our team of expert designers ensure every detail is perfected for production.

2. Production

In our manufacturing process, we use a combination of traditional craftsmanshiph and cutting-edge technology to bring designs to life. We use techniques such as wax casting, 3D printing, and handcrafting, and each step—from mold creation to metal casting—is executed to achieve the highest precision and quality.

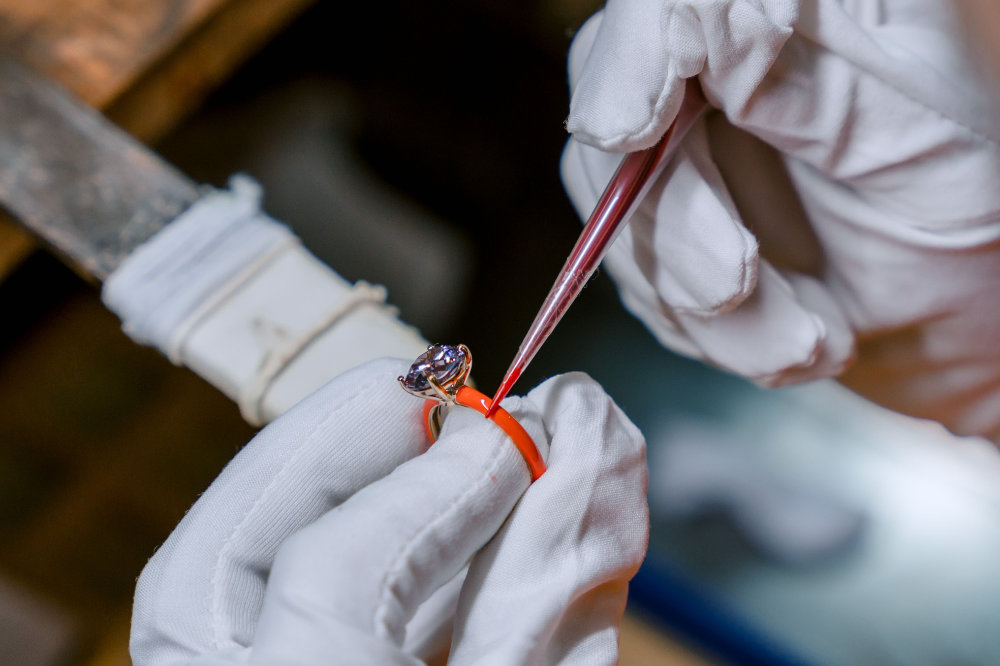

3. Setting

Stone setting is a vital stage in jewelry creation, requiring precision and skill to securely mount stones while maximizing their brilliance. We offer a full range of setting options, including prong, bezel, pavé, and channel settings, each tailored to the specific design and stone type. This process is essential to the final appearance and durability of the jewelry, bringing each design to its full potential.

4. Finishing

The finishing process is where the piece takes on its final appearance. Techniques such as polishing, buffing, and plating are applied to refine the surface, enhance shine, and improve durability. We offer various plating options to protect against tarnishing and wear, ensuring long-lasting brilliance and quality.

5. Quality Control

Stringent quality control protocols are applied throughout every stage of production, with final inspections being the most comprehensive. Our quality assurance team performs detailed checks on every piece, focusing on design accuracy, material integrity, stone setting security, and finishing quality.

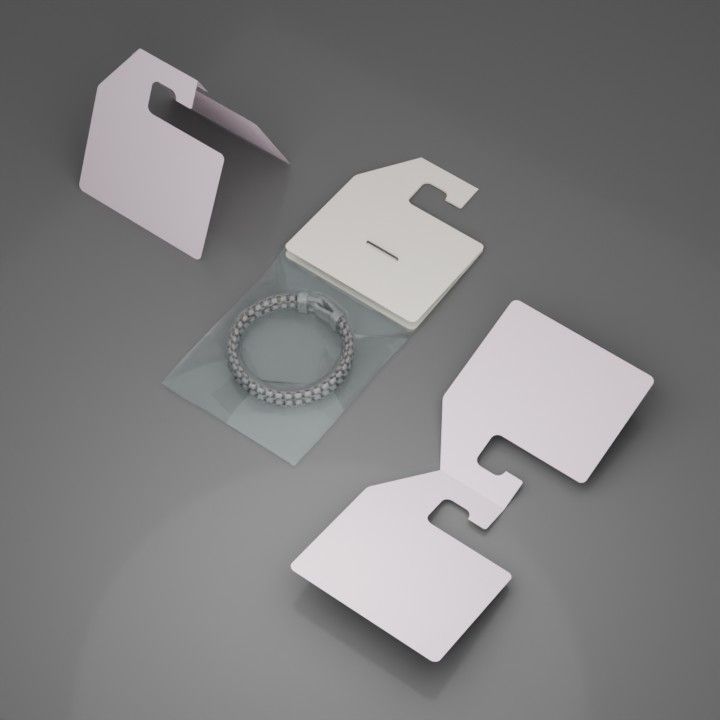

6. Packaging

Once the jewelry is complete, packaging is the final step in delivering a polished product. We offer custom packaging solutions designed for both protection and presentation, with options that include eco-friendly materials and high-end finishes. The goal is to ensure that each piece not only arrives safely but also creates a lasting impression when it reaches the customer.

Packaging

We understand that packaging is an essential part of the jewelry experience. Our packaging team is dedicated to creating customized packaging designs that enhance the presentation of products.

Section D, N2 Street, Hoa Mac Industrial Park, Duy Tien District, Ha Nam Province, Vietnam